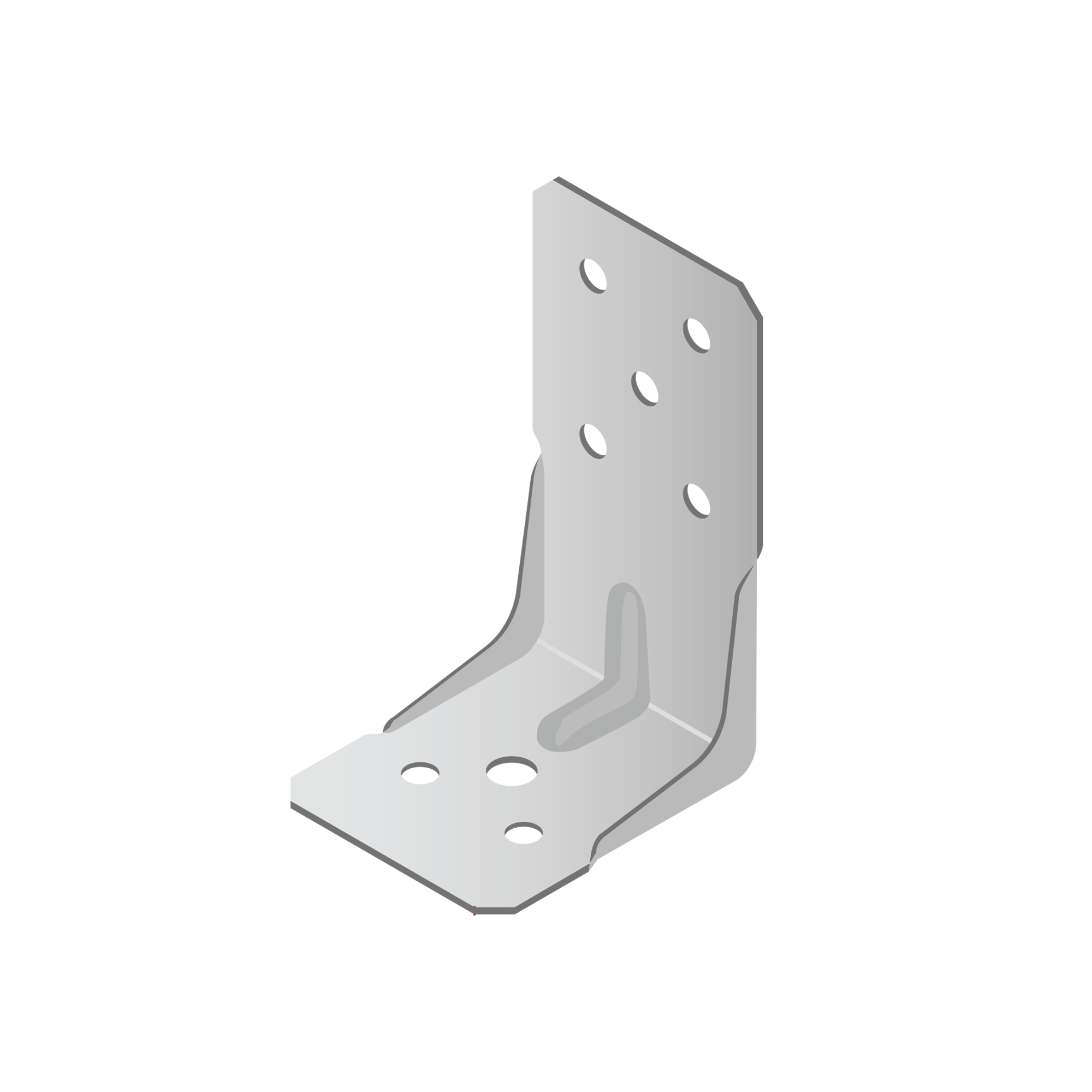

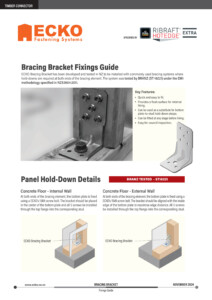

Bracing Brackets

15kN Panel Hold-Down Kit

![]()

ECKO Bracing Bracket has been developed and tested in NZ to be installed with commonly used bracing systems where

hold-downs are required at both ends of the bracing element. The system was tested by BRANZ (ST-18221) under the

EM1 methodology specified in NZS3604:2011.

Product

Panel Hold-Down Details

Specified by

Concrete Floor – Internal Wall

At both ends of the bracing element, the bottom plate is fixed using a ECKO’s 15kN screw bolt. The bracket should be placed in the center of the bottom plate and all 5 screws be installed through the top flange into the corresponding stud.

Concrete Floor – External Wall

At both ends of the bracing element, the bottom plate is fixed using a ECKO’s 15kN screw bolt. The bracket should be aligned with the inside edge of the bottom plate to maximise edge distance. All 5 screws be installed through the top flange into the corresponding stud.

Step 1

Using the correct masonry drill bit,

drill a hole to the required embedment

+10mm. Ensure that the minimum edge

distance of 55mm is adhered too.

Step 2

Clean dust and debris from hole.

Step 3

Put the bracket in place and screw in

anchor using torque wrench or impact

wrench until flange head is firmly secured

against the bracket. DO NOT OVER-

TIGHTEN. Install all 5 screws in top flange.

HotEdge

The ECKO M10 x 155 Screw Bolt (Orange Head) was developed in partnership with Firth to provide a fixing for a 90mm bottom plate where Firth’s RibRaft HotEdge Extra insulation is used and can be substituted for the blue headed screw bolt provided. The Orange head screw bolt has been BRANZ tested (ST18050-01-02) and meets the required 15kN pullout rating to be used in common bracing systems, along with 3kN out of plane and 2kN in plane requirements set out in NZ3604:2011.

Step 1

Using a 10mm masonry drill bit, drill a

hole to the required embedment +

10mm. Ensure that the minimum edge

distance (from outside of insulation) of

58mm is adhered too.

Step 2

Clean dust and debris from hole.

Step 3

Put the bracket in place and screw in

anchor using torque wrench or impact

wrench until flange head is firmly secured

against the bracket. DO NOT OVER-

TIGHTEN. Install all 5 screws in top flange.

Note

* 15kN hold down is dependent on a minimum of 20MPa concrete.

** Two additional holes are provided on the bottom flange to allow specific engineered design for alternative fixings (ie balustrade fixing, post fire stability, etc)